Production process

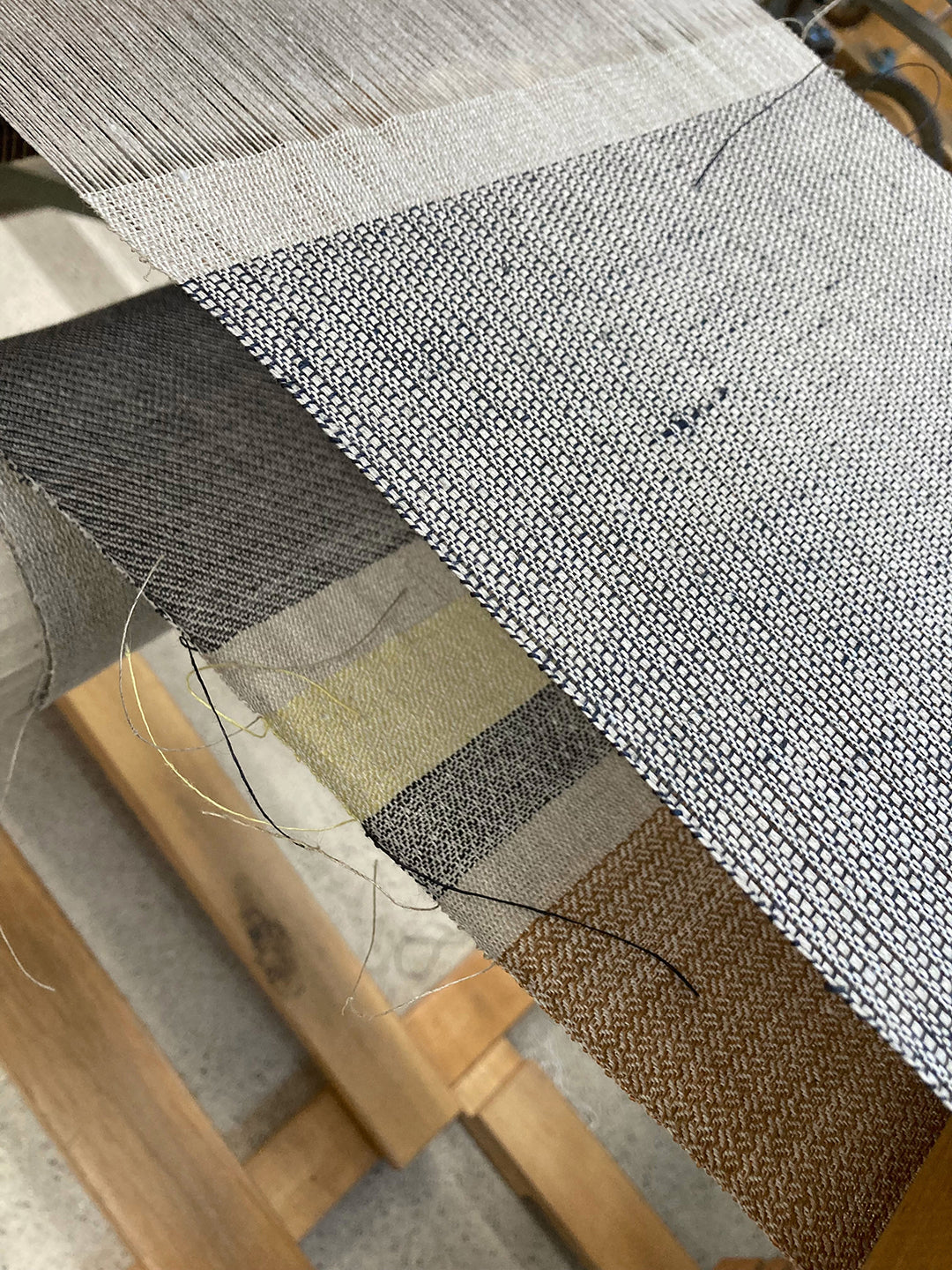

From the seed to the finished fabric, neri fabrics are made from 100% flax. Neri works together with Swissflax, which is committed to the revival of flax cultivation in Switzerland. The flax is sown, harvested, roasted and pressed into bales on around 7.5 hectares in the Emmental. Due to the lack of infrastructure, further processing takes place in nearby European countries: the fibers are broken down in Holland and spun into yarn in Bergamo, Italy. In the workshop in Lucerne, new fabrics are created from the spun linen yarn on hand looms. The designs are adapted to the technical requirements of industrial production. Orders are collected on the basis of the patterns and selected patterns are woven industrially in the Minnotex weaving mill. The warp consists of boiled raw yarn, while the weft yarn is raw or dyed. In collaboration with Anne Scheidegger from Botanitex, tests have already been carried out with vegetable dyeing (oak and woad) of the spun raw yarn. For the next production run and a larger batch, the raw yarn will be dyed at the Fritsch dye works in Vienna. The long-term goal is to be able to carry out this step in the immediate vicinity. However, this still requires development time. Finally, the linen fabrics are washed and steamed at Johann Müller Textil.